The breadth of design has to be seen to be believed. The level of "workWOmanship" is amazing.

Take just one example: kilims and rugs; they are hand made; row-by-row or knot-by-knot and created throughout the entire kingdom.

Each region is known for a particular style, design or method which has been handed down, mother to daughter, for generations.

Often, the entire process from sheep to finished kilim, is the work of one woman who has mastered all the steps over many years.

These days synthetic dyes are mostly used to achieve the vibrant colour combinations Moroccans love so much. In the past, wool was naturally dyed and the henna plant was widely used. It yields beautiful ginger gold and brown hues.

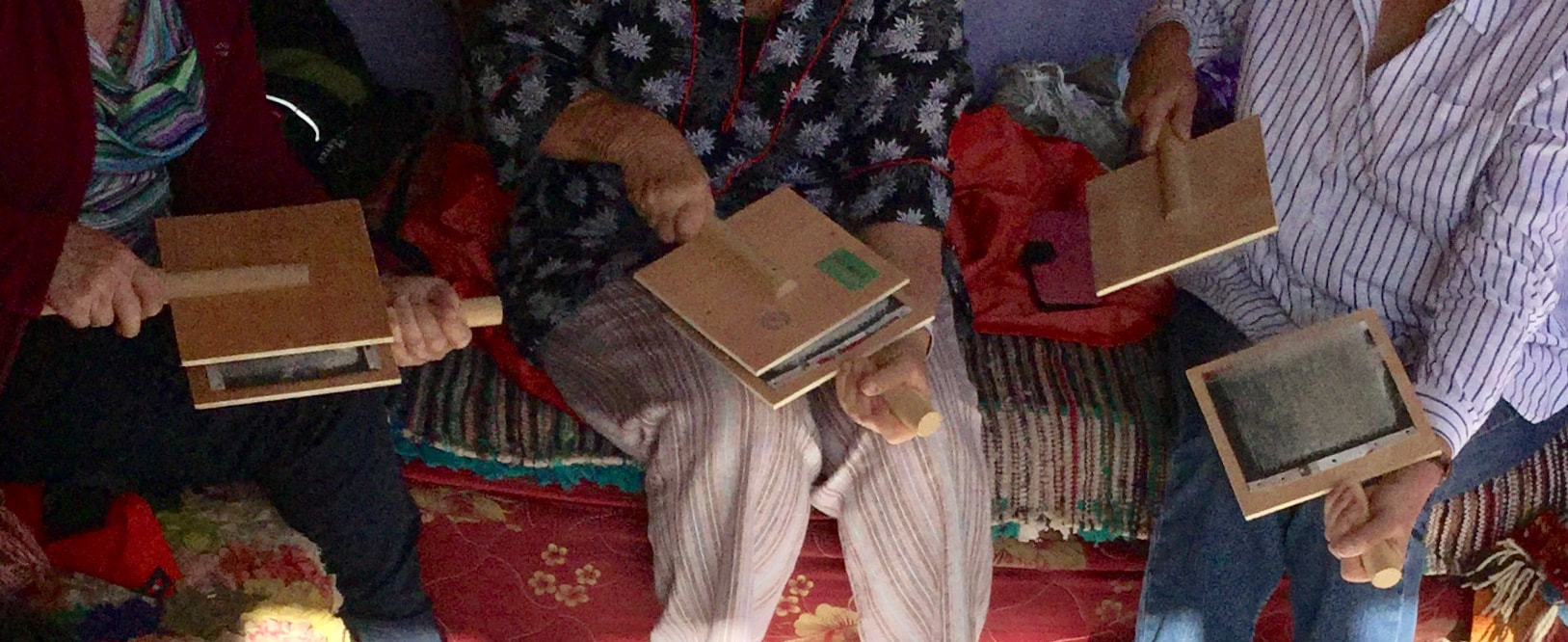

In the Draa Valley, in Southern Morocco, Mina, who still dyes with henna, very generously shares her skills with my Purely Textiles tour groups. She shows us each step and we participate in her process:

Mina coats the pot with mud and ash to make it easier to clean after.

Into the pot goes water, dried henna leaves and seeds.

Dried pomegranate skin is added as a fixer. Not the edible variety but a bitter, smaller type.

We also add some white silk cloth samples.

| After just 15 minutes of boiling you can see the colour forming. Another 15 minutes and the fire is allowed to die down, the lid goes on and the contents left to steep overnight. The wool hanks and silk cloth are hung to dry. Here are the hanks, after we rolled them into two ginger balls, nestled in the golden-hued silk. |

RSS Feed

RSS Feed